Optimisation and approvals of friction management

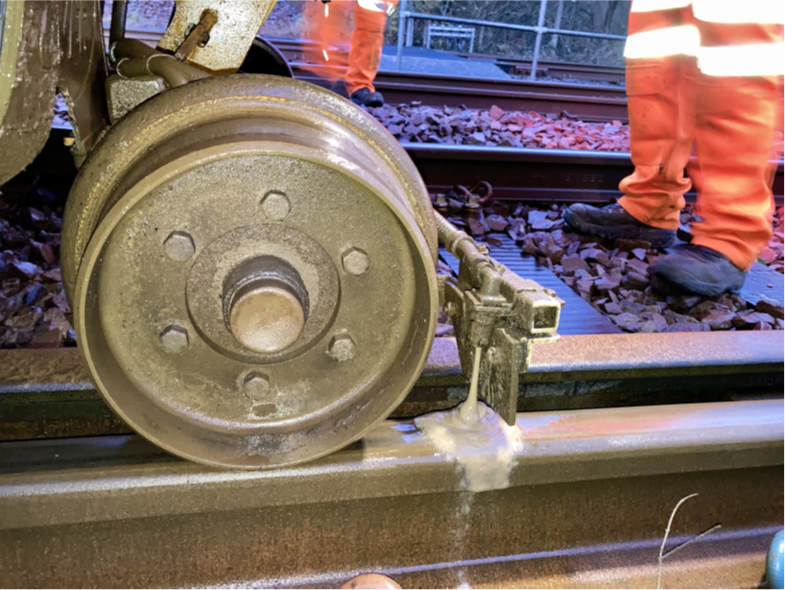

Laboratories provide controlled variables, on track provides a representative environment. We can do them both for development, optimisation and approvals of current and novel products.

Resultant friction, carry-down and consumption can all be measured using our tribometer.

Low Adhesion Simulation

Representative, repeatable and measurable low adhesion conditions for testing or optimising rail cleaning or traction enhancing products, year round.

In our workshop or out on track.

Validated with braking trials.

Published in Rail Safety and Standards Board protocols “COF-UOS22-04”.

Friction Surveys

Multiple sources of contaminants?

Non-visible contaminants?

What is the role of water, or specific environmental conditions?

Localised or widespread friction anomalies?

Contaminants at site of low adhesion, or picked up on wheel from earlier in the journey?

Our granular friction data provides answers

Friction Library

Over the last two years we have been building a world-leading friction library.

We can measure a “datum” or reference point for a specific location and compare against a global database.

This is leading to a better understanding of whether friction is within norms for the specific environment, or anomalous and requiring treatment.

Environmental chamber

Friction, as well as the behaviour of management products, is dependent on temperature and humidity.

Our environmental chamber allows friction testing down to -20 Celcius.

For simulating year-round conditions and extreme weather events.