Case Studies

Top of rail friction management

Top-of-rail friction management products are oil or water based films designed to reduce wear, rolling contact fatigue and noise (squeal). They are applied via on-board or wayside applicators.

If used correctly they can extend asset life, but the transparent films are difficult to detect and optimise.

Friction measurements can help determine key performance indicators such as resultant friction with different application amounts, carry-down and consumption.

This helps work towards a smarter and system-specific strategy including product type, application type & amount, interval and location.

Carry-down

Consumption

Application

Friction management on tram systems

Our tribometer can be used to inspect a wide range of rail types, including grooved and embedded rail.

Noise in urban systems, tight curvatures and frequent accelerations mean controlled friction management is essential.

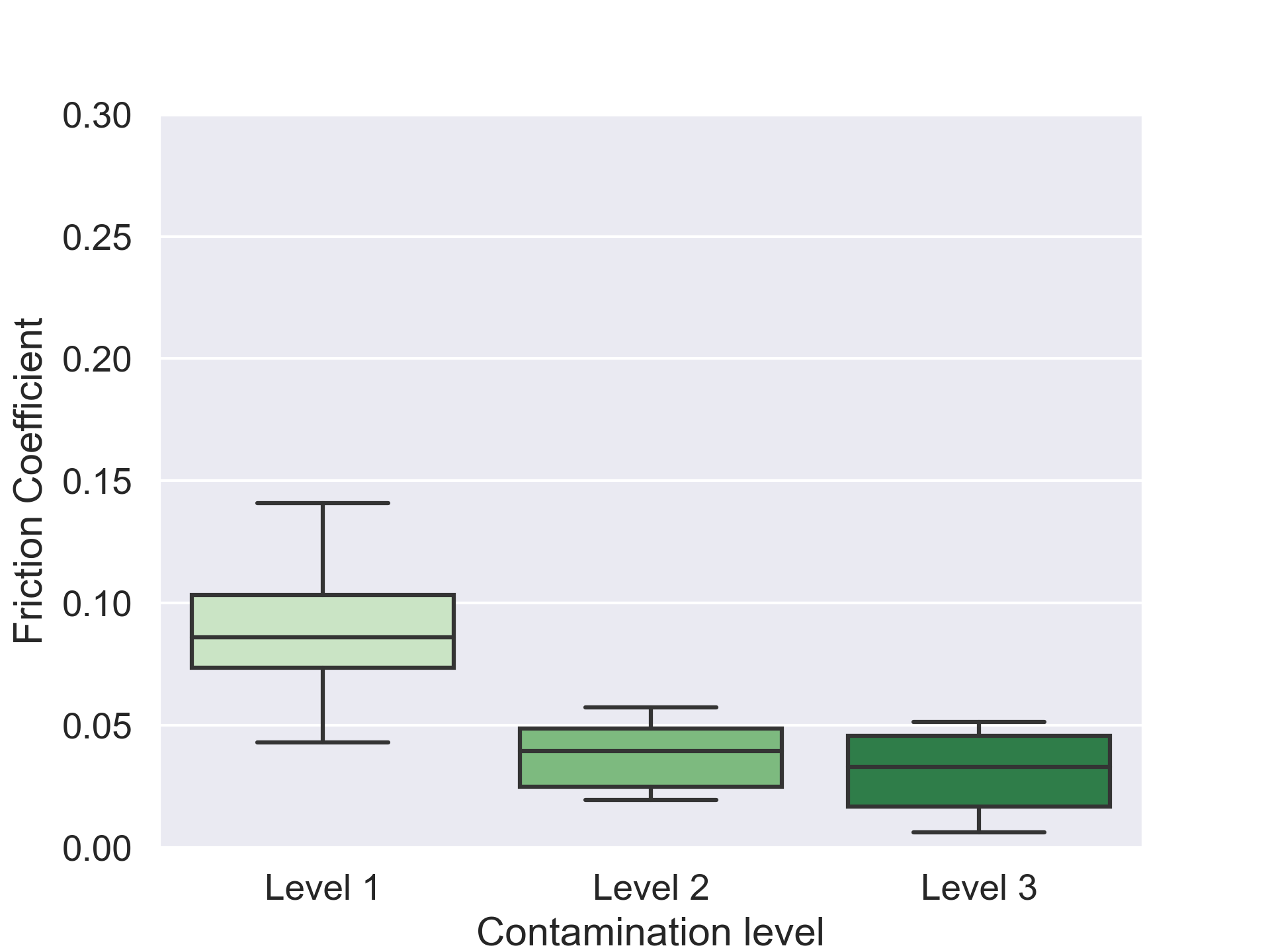

The surface level rail is susceptible to a wide range of contaminants. These can be visibly similar, but have vastly different effects on friction.

Our measurements feed into a site-specific friction management strategy, for improved passenger and resident comfort, enhanced asset life and predictable acceleration.

Optimisation of novel rail cleaning method

Optimisation of on-board rail cleaning treatment for different leaf layer contamination levels.

Including:

Cleaning speed

Cleaning power

Nozzle diameter

Nozzle placement

Granular data provided by portable tribometer (>500 measurements), validated with train braking trials.

“White, B., Watson, M., Jaffe, J., & Lewis, R. (2025). A field methodology to assess the performance of rail cleaning, using a new portable tribometer. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 239(5), 421-430.”

Conference proceedings

Press releases

International Collaborative Research Initiative on Wear and Rolling Contact Fatigue, Vienna 2024

https://www.icri-rcf.org/downloads/

Nordic Seminar on Rail Technology, Stockholm 2024

https://www.kth.se/polopoly_fs/1.1342849.1718025124!/1_2_WR_Interaction.pdf